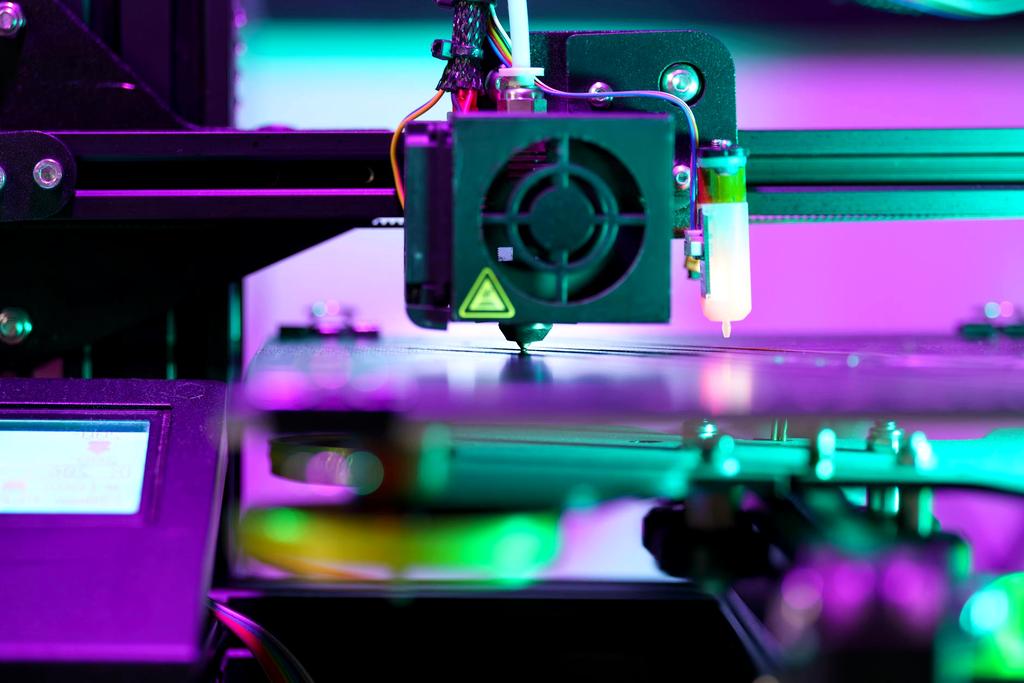

The Future of Manufacturing with AI-Powered Robotics

Revolutionize your industrial processes with cutting-edge robotic solutions enhanced by artificial intelligence. Increase efficiency, reduce costs, and achieve unprecedented precision.

Revolutionize your industrial processes with cutting-edge robotic solutions enhanced by artificial intelligence. Increase efficiency, reduce costs, and achieve unprecedented precision.

Our state-of-the-art technology brings unparalleled capabilities to industrial automation

Our robots continuously learn from operations, adapting to changing conditions and improving performance over time without human intervention.

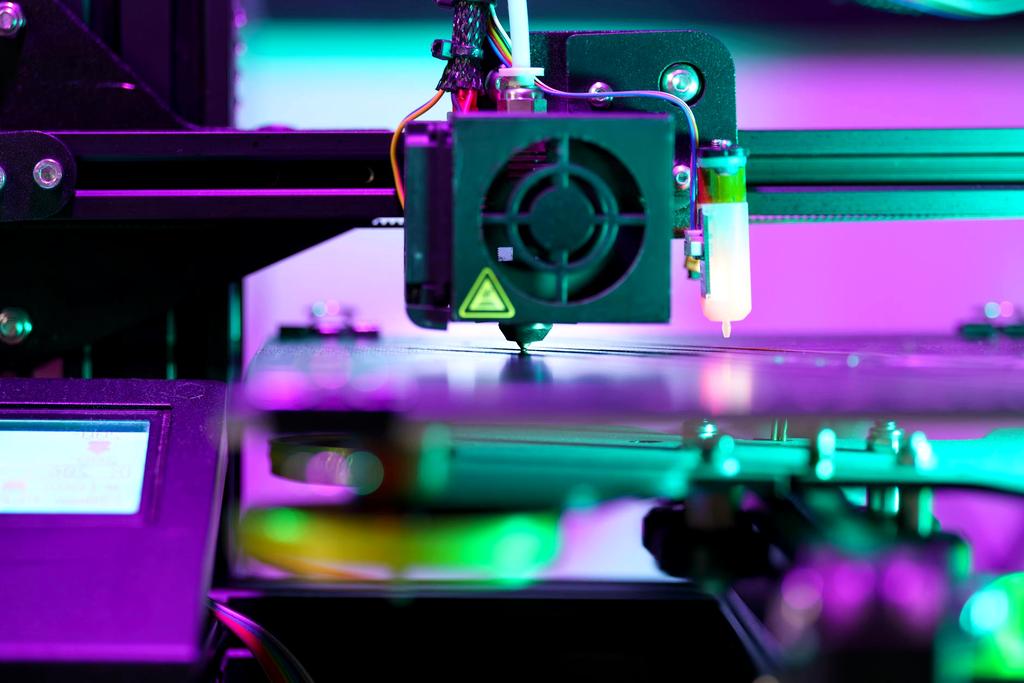

Multi-spectrum cameras and sensors allow our robots to perceive their environment with unprecedented accuracy, even in challenging conditions.

AI algorithms forecast potential equipment failures before they occur, minimizing downtime and extending the operational lifespan of your machinery.

Our cobots work safely alongside human operators, combining machine precision with human flexibility for optimal production efficiency.

Multiple redundant safety systems ensure workplace security, with AI-powered risk assessment constantly monitoring operations.

Comprehensive dashboards provide instant insights into productivity, quality control, and operational efficiency metrics.

See how our AI-powered robotics transformed these industries

Implemented AI vision systems and adaptive robotic arms that increased production efficiency by 35% and reduced defects by 28% for a major automotive manufacturer.

Deployed ultra-precise robotic systems that maintain sterile conditions and achieve 99.99% accuracy in medication handling and packaging.

Implemented food-safe robots with advanced sensing capabilities that doubled throughput while maintaining stringent quality control standards.

Meet the brilliant minds behind our revolutionary AI robotics technology

Chief Robotics Scientist

Former MIT researcher with 15+ patents in adaptive robotics systems.

AI Systems Architect

Pioneered revolutionary machine learning algorithms for complex industrial applications.

Lead Mechanical Engineer

Specializes in designing robust, adaptive mechanical systems for harsh environments.

Software Integration Lead

Expert in developing seamless interfaces between AI systems and robotic hardware.

Real feedback from industry leaders who have implemented our solutions

Operations Director, TechManufacture Inc.

"The implementation of Nexus Robotics' AI-powered systems transformed our production line. We've seen a 42% increase in output while reducing operational costs by nearly a third. Their support team has been exceptional throughout the entire process."

VP of Engineering, AutoInnovate

"We were hesitant about integrating AI robotics into our precision manufacturing processes, but the results have been remarkable. The adaptive learning capabilities have improved our quality control beyond what we thought possible."

Innovation Lead, PharmaFuture Labs

"The sterile-environment robots have revolutionized our pharmaceutical production line. The precision and reliability have allowed us to scale operations while maintaining our stringent quality standards. Worth every penny of our investment."

CEO, Quantum Electronics

"We integrated their AI vision systems and adaptive robotics across three facilities, and the results have exceeded our expectations. The predictive maintenance feature alone has saved us millions in potential downtime."

Schedule a free consultation with our experts to discuss your specific needs